Category: World of Magnets

Heavy Duty Magnets

How do Magnets Work?

Rare Earth Magnets

What is a Magnetic Field?

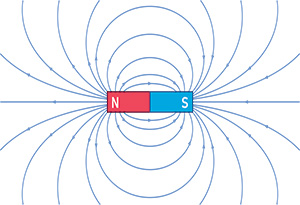

A magnetic field is a phenomenon that occurs when electrically charged particles move through space. It is a force that can attract or repel other magnetic materials and can be detected using a compass or other magnetic instruments.

Magnetic fields are created by moving electric charges. This means that any object with an electric charge can create a magnetic field. However, the strength of the it depends on the speed and direction of the movement of the electric charges.

The strength of a magnetic field is measured in units called Tesla (T) or Gauss (G). One tesla is equivalent to 10,000 Gauss. Magnetic fields can range from very weak, such as the Earth’s magnetic field, which is about 0.00005 T, to extremely strong, such as the magnetic field inside a magnetic resonance imaging (MRI) machine, which can be up to 3 T.

Magnetic fields have many practical applications in everyday life. They are used in MRI machines to create images of the body’s internal organs, in electric motors to produce motion, in generators to produce electricity, in credit card readers to read information stored on a magnetic strip, and in many other devices.

In addition to their practical applications, magnetic fields also play a crucial role in the behavior of many objects in the universe. For example, the magnetic field of the Sun is responsible for the solar wind, a stream of charged particles that flows out from the Sun and affects the Earth’s atmosphere and magnetic field.

In conclusion, a magnetic field is a force that can attract or repel magnetic materials and is created by the movement of electric charges. They are measured in units of Tesla or Gauss and have many practical applications in everyday life as well as in the behavior of objects in the universe.

What is a Magnetic Domain?

What is Magnet Fishing?

Will a Magnet Stick to Stainless Steel?

How to Make a Magnet?

- Choose a ferromagnetic material – Ferromagnetic materials are materials that can be magnetized, and they include iron, nickel, and cobalt. You can use a piece of metal, such as a paperclip or nail, or purchase a ferromagnetic material from a hardware store.

- Align the material’s domains – The ferromagnetic material’s magnetic domains, which are small regions within the material that have their own magnetic fields, must be aligned to make a magnet. To do this, expose the material to a strong magnetic field. You can use a permanent magnet or an electromagnet to create this field.

- Stroke the material – After the material has been exposed to the magnetic field, stroke it in one direction with a permanent magnet. This process will help to align the material’s domains in the same direction, creating a stronger magnetic field.

- Test the magnet – To test the magnet’s strength, try to pick up small metal objects with it, such as paper clips or nails. The magnet should attract these objects easily if it is strong enough.