|

||

|

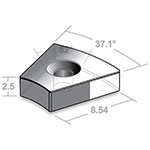

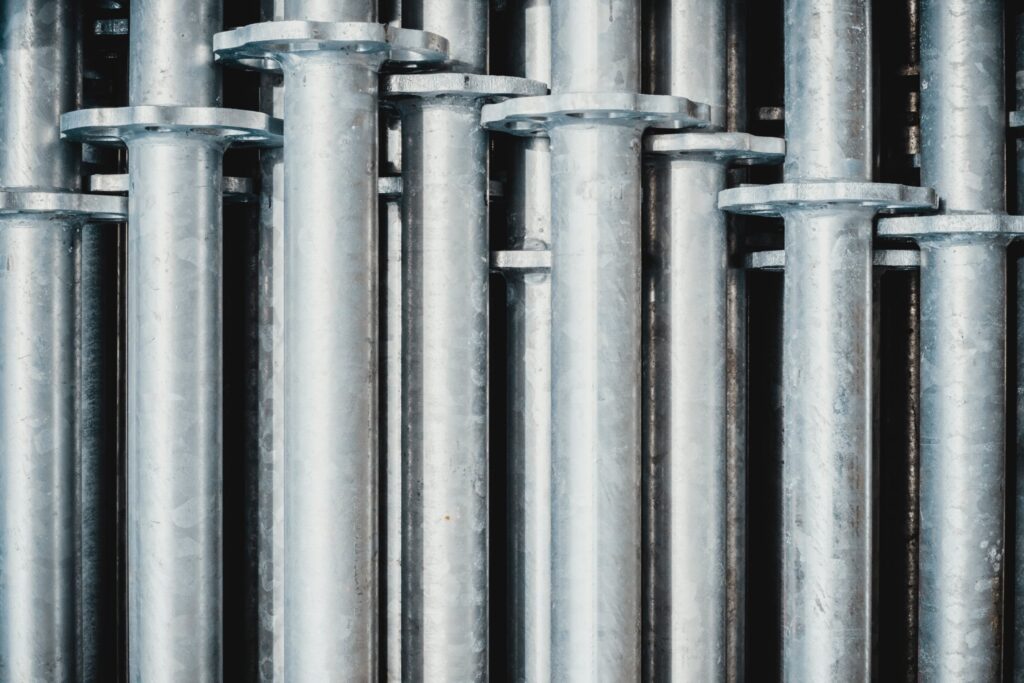

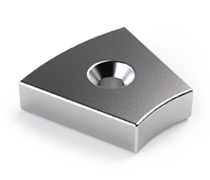

Drilling Holes Glass cutting or Masonry drill bits (like the ones shown below) work best. The higher-end “diamond burr bits” also work, the cheap ones found in your generic Dremel kit don’t. It is important to have a bit that can break through the hard nickel coating of the magnets, as well as slowly and carefully remove the sintered magnet material.

|

Category: Topic

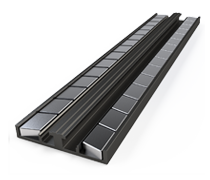

Buy Powerful Neodymium Linear Motor Magnet

Laser-Etching

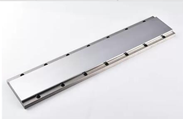

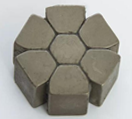

Buy Powerful Neodymium Halbach Array Magnet

GroundBreakingPR

Date: January 6, 2021

FOR IMMEDIATE RELEASE Contact Information Name: Judith M. Guido Email: judithg@amazingmagnets.com Phone: 818 800 0135California company, Amazing Magnets, relocates its Global Headquarters to Texas

Company to Break Ground in Round Rock, Texas on January 7, 2021

ROUND ROCK, TX – As a result of year-over-year growth, Amazing Magnets is relocating its business operations from Anaheim, California and building a state-of-the art global headquarters in Round Rock, Texas. The new headquarters will showcase an engineering design workspace, a media and learning center, and an innovative warehouse facility. After exploring several locations, the company was drawn to Round Rock for its entrepreneurial spirit, access to world-class talent, and beneficial cost of living. What sealed the deal for Amazing Magnets’ team is a core value it shares with the city of Round Rock–the importance of community.

Founder and Chief Executive Officer Tim Boettcher said, “Our roots are that of a family-owned business with a focus on giving back to the community combined with a passion for continuous learning guided by a unique global strategy and an incredibly talented team. After visiting Round Rock and witnessing its economic growth, diversification and meeting its people, we felt like we had found our home away from home. Everyone was so welcoming, kind and supportive.”

On January 7, 2021, the Amazing Magnets team, with invited guests including dignitaries from the Round Rock Chamber of Commerce, Council, County Commission, business community and media, will break ground on its 40,000 square-foot global headquarters. Leadership from the Altman Development Group will also be on hand to celebrate.

Amazing Magnets designs, manufactures, and distributes magnetic-related devices and products. “The Amazing Magnets team and organization exemplifies the type of people and businesses we want to attract and welcome to the Round Rock community. We are here to help and support them in their growth and hopefully become an integral part of their success,” said Jason Ball, the CEO of the Round Rock Chamber of Commerce.

ABOUT – Amazing Magnets is a global company that designs, manufactures and distributes magnetic-related devices and products. It also provides the crucial services associated with these mission-critical functions including engineering, testing, prototyping, contract administration, regulatory compliance and warehousing.

Temporary Headquarters 595 Round Rock West Drive – Suite # 203

Round Rock, Texas 78681

www.amazingmagnets.com

![]()

Gluing Neodymium Magnets

Strong Magnet Marker Holder

Metals that are attracted to magnets

Amazing Magnets Credit Terms

|

Amazing Magnets, Line of Credit Amazing Magnets offers a 30-day line of credit for qualified businesses. You must be legally authorized to access and dispense the information requested in the Amazing Magnets credit request verification form. If approved the company agrees to make payments within the agreed-upon terms. Returned checks will be subject to a $25.00 service charge. The applicant’s company will be responsible for all reasonable legal fees and collection charges (including document delivery fees, banking fees, and collection fees) on delinquent accounts. Accounts that are delinquent may have credit revoked and all pending orders are subjected to cancellation. Purchase orders paid with a credit card will be subject to a 3% service charge. Approval usually takes 1-2 weeks to verify information and contact references Required information includes but is not limited to: Entity Information Trade References |