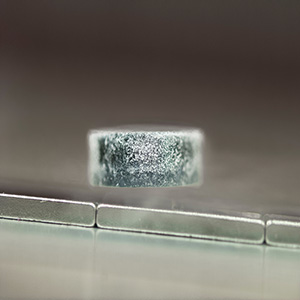

In the realm of transportation, one concept stands out as both complex and promising: magnetic levitation, often referred to as maglev technology. This revolutionary mode of transportation has captured the imagination of engineers, innovators, and commuters alike, offering the potential for ultra-fast, frictionless travel. The foundational principles of magnetic levitation were understood in the early 20th century, with significant advancements occurring throughout the mid to late 20th century. Practical applications of maglev technology for transportation emerged in the latter part of the 20th century, with the first operational maglev train, the SCMaglev, being developed and tested in Japan in the 1970s and 1980s. So, while the principles behind maglev technology have been understood for a long time, its practical application for transportation purposes has only recently begun to develop.

In the realm of transportation, one concept stands out as both complex and promising: magnetic levitation, often referred to as maglev technology. This revolutionary mode of transportation has captured the imagination of engineers, innovators, and commuters alike, offering the potential for ultra-fast, frictionless travel. The foundational principles of magnetic levitation were understood in the early 20th century, with significant advancements occurring throughout the mid to late 20th century. Practical applications of maglev technology for transportation emerged in the latter part of the 20th century, with the first operational maglev train, the SCMaglev, being developed and tested in Japan in the 1970s and 1980s. So, while the principles behind maglev technology have been understood for a long time, its practical application for transportation purposes has only recently begun to develop.

Understanding Maglev Technology

At its core, magnetic levitation relies on the fundamental principles of electromagnetism to suspend and propel vehicles along a specially designed guideway without the need for traditional wheels, axles, or rails. This allows for achieving extreme speeds without creating excessive friction. The two primary types of maglev technology are electromagnetic (EMS) and electrodynamic (EDS) systems. EMS systems utilize electromagnets to create a magnetic field that repels the train from the guideway, allowing it to levitate. This is achieved by passing an electric current through coils in the guideway, which generates a magnetic field that interacts with other electromagnets or permanent magnets on the underside of the train. EMS systems are known for their stability and ability to adjust to changes in load and speed. On the other hand, EDS maglev systems utilize the principles of electromagnetic induction. In an EDS system, the magnets on the train induce currents in the guideway coils as they pass over them. These induced currents create a magnetic field that repels the magnets on the train, causing it to levitate. EDS systems are typically known for their high-speed capabilities and efficiency, as they don’t require power to be constantly supplied to the guideway coils. This makes EDS systems a compelling choice for high-speed trains.Real-life Examples

While still in its infancy compared to traditional modes of transportation, maglev technology has demonstrated significant potential through various applications around the world. One of the most prominent examples is the Shanghai Maglev Train in China, which is the world’s fastest commercial maglev train, achieving speeds of up to 267 mph! This remarkable achievement underscores the immense capabilities of maglev technology for high-speed rail systems. Beyond Shanghai, maglev trains have been proposed and developed in several countries to address urban congestion, enhance intercity connectivity, and reduce travel times. Projects such as the proposed Chūō Shinkansen in Japan and the experimental Transrapid system in Germany serve as testaments to ongoing efforts to implement maglev technology on a larger scale.

While still in its infancy compared to traditional modes of transportation, maglev technology has demonstrated significant potential through various applications around the world. One of the most prominent examples is the Shanghai Maglev Train in China, which is the world’s fastest commercial maglev train, achieving speeds of up to 267 mph! This remarkable achievement underscores the immense capabilities of maglev technology for high-speed rail systems. Beyond Shanghai, maglev trains have been proposed and developed in several countries to address urban congestion, enhance intercity connectivity, and reduce travel times. Projects such as the proposed Chūō Shinkansen in Japan and the experimental Transrapid system in Germany serve as testaments to ongoing efforts to implement maglev technology on a larger scale.