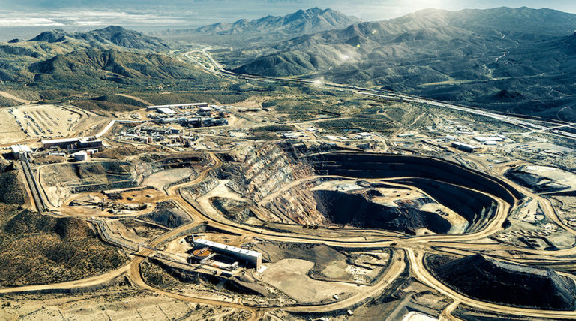

Mountain Pass Rare Earth Mine: From Discovery to Strategic Revival

Listen to this Article

Mountain Pass Rare Earth Mine: From Discovery to Strategic Revival

1. Discovery and Early Development (1949–1960s)

2. Peak Global Dominance (1960s–1980s)

Throughout the 1960s and 70s, Mountain Pass emerged as the world’s leading supplier of rare earths. The mine's primary products werre: cerium, lanthanum, neodymium, and praseodymium. These REEs became increasingly crucial for applications such as color televisions, military lasers, and early computing systems as technology continued to advance.

In 1977, the operation was acquired by Unocal (Union Oil Company of California), which continued to develop the mine’s production capabilities. By the early 1980s, the U.S. controlled the majority of global rare earth production, with Mountain Pass at the center of that dominance.

3. Environmental Issues and Decline (1990s–2002)

The decline began in the late 1980s and 1990s, largely due to environmental mishaps. Leaks from the wastewater pipeline resulted in radioactive spills, drawing heavy regulatory scrutiny. Coupled with this, China began to undercut global prices through aggressive investment and export incentives in its own REE industry.

Facing high environmental remediation costs and plunging market prices, Unocal suspended mining operations at Mountain Pass in 2002. Though some stockpiled material was processed intermittently, the U.S. ceded rare earth dominance to China during this period.

4. Molycorp Revival and Bankruptcy (2008–2015)

Molycorp acquired Mountain Pass in 2008 with ambitions to reestablish U.S. rare earth leadership. Their $1.7 billion “Project Phoenix” aimed to modernize and restart mining and refining operations. Molycorp went public in 2010 and briefly became a market darling, driven by fears over Chinese export restrictions and growing demand for clean technology materials.

However, the project faced technical challenges, lower-than-expected recoveries, and cost overruns. With global REE prices collapsing by 2015, Molycorp filed for bankruptcy.

5. New Ownership and Rebirth (2017–2020)

In 2017, MP Mine Operations LLC—a consortium including U.S. hedge funds JHL Capital Group, QVT Financial LP, and China’s Shenghe Resources (non-voting minority shareholder), acquired Mountain Pass out of bankruptcy for $20.5 million. The rebranded company, MP Materials, restarted mining that same year.

By 2019, Mountain Pass was producing over 30,000 metric tons of rare earth oxide equivalent annually, representing roughly 15% of global output. However, most of this material was exported to China for processing which made it a critical national security vulnerability.

6. U.S. Government Support and Domestic Investment (2020–2023)

Recognizing the strategic risk of relying on Chinese refining, the U.S. Department of Defense began funding initiatives to restore domestic processing capabilities. MP Materials secured federal contracts to expand operations and build a rare earth magnet manufacturing facility in Texas.

The goal was clear: to establish a vertically integrated rare earth supply chain from mine to magnet, fully within U.S. borders. By 2023, MP was processing about half of its production domestically, with plans to achieve full independence from Chinese downstream processing.

7. Strategic Break from China (2024–2025)

In April 2025, a major strategic shift occurred. MP Materials halted all exports of rare earth concentrates to China, a move triggered by Beijing’s imposition of 125% tariffs on U.S. rare earth products. This marked a clear departure from the company's historical reliance on Shenghe Resources as its primary buyer, accounting for over 70% of revenue in 2024. Total Impact to the US market from the tariffs included the 125% US retaliatory tariffs, the 10% baseline tariffs and the 10% fentanyl tariffs yielding a total tariff from China at a staggering 145% plus any previous individual baseline tariffs that existed. For the magnets produced using the REE (such as NdFeB Rare Earth Magnets) that equated to a total tariff of 147.2%.

In response, MP Materials accelerated its U.S.-based processing and magnet manufacturing initiatives, doubling down on investments in its Mountain Pass facilities and the Texas magnet plant. According to company statements, this pivot was a deliberate effort to reindustrialize the U.S. rare earth supply chain and shield it from geopolitical disruptions.

8. Global Partnerships and Expansion (May 2025)

Expanding its reach, MP Materials entered into a memorandum of understanding with Ma'aden, Saudi Arabia's state-owned mining company, to jointly develop a rare earths supply chain in the Middle East. This partnership aims to enhance global supply security and diversify refining capabilities beyond China and the U.S.

9. Outlook and Strategic Implications

Mountain Pass today is not just a mine, it is a cornerstone of U.S. economic and national security strategy. With tensions rising over global resource dependencies and supply chain vulnerabilities, MP Materials has positioned itself at the forefront of a new industrial policy landscape.

Key challenges remain, including:

- Full domestic capability for heavy REE separation

- Dependence on imported processing reagents

- Scaling magnet production to commercial levels

Nevertheless, with nearly $1 billion invested, strong government support, and a decisive pivot away from China, Mountain Pass is again becoming a symbol of American resource resilience.